MWM

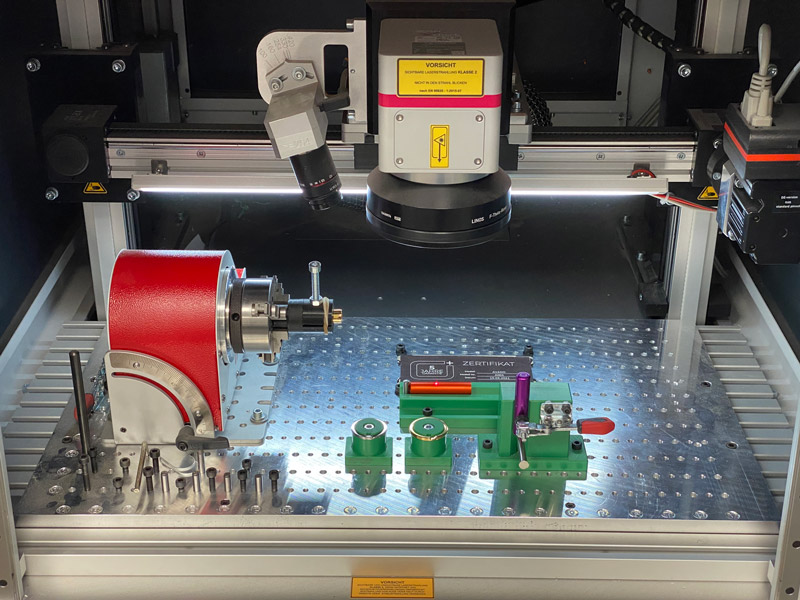

Laser labeling / laser engraving

Diverse - multicolored - individual

High power laser

Large laser area

Laser example

For further information please click on the images.

FAQ - MOPA and fibre lasers for laser marking

What is a MOPA laser?

A MOPA laser (Master Oscillator Power Amplifier) is a type of fibre laser in which the pulse duration can be variably adjusted. This allows the laser pulses to be customised for different materials and applications. MOPA lasers offer flexibility in marking by allowing the pulse duration and frequency to be set independently of each other.

What advantages do MOPA lasers have over standard fibre lasers?

MOPA lasers offer variable pulse duration and higher frequencies, which leads to better results when marking plastics and metals. They are particularly useful for black marking on anodised aluminium and coloured marking on steel.

Which materials can be marked with MOPA and fibre lasers?

MOPA and fibre lasers can mark a wide range of materials, including

Metals: steel, stainless steel, aluminium, copper, brass, titanium

Plastics: acrylic, ABS, PET, PETG, PC, PMMA

Other materials: leather, acrylic, textiles, wood, glass, paper

What applications are there for MOPA and fibre lasers?

Applications range from the labelling and engraving of metals and plastics to the production of QR codes, serial numbers and logos. They are widely used in various industries such as the automotive industry, electronics and medical technology.

How does a fibre laser work?

A fibre laser uses an optically pumped glass fibre that is doped with rare earths such as ytterbium. The pump diodes generate light that is amplified in the glass fibre to produce a powerful laser beam. This process enables high efficiency and precise labelling results.

What power should a fibre laser have?

The required power depends on the application:

Low power (up to 20W): for simple labelling on plastics and thin metal coatings.

Medium power (30-60W): For engraving metals such as stainless steel and aluminium, suitable for industrial applications

What are the main components of a fibre laser?

A fibre laser consists of:

Pump diodes: Convert electrical energy into optical energy.

Passive fibre: Guides the laser beam.

Collimator: Shapes the laser beam into a parallel beam.

Isolator: Protects the laser from harmful back reflections.

Control unit: Controls laser parameters such as power and frequency.

What are the main differences between MOPA and standard fibre lasers?

The main differences lie in the variable pulse duration and the higher frequency range of MOPA lasers, which gives them greater flexibility and better results with certain materials.

MWM Gmbh & Co. KG also offers other mechanical services in addition to laser labeling, such as

▪ Cutting/sawing

▪ CNC processing

▪ Punching

▪ Welding threaded studs

▪ Press in threaded bolts

▪ Engraving

▪ Bending

▪ Welding

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de