MWM

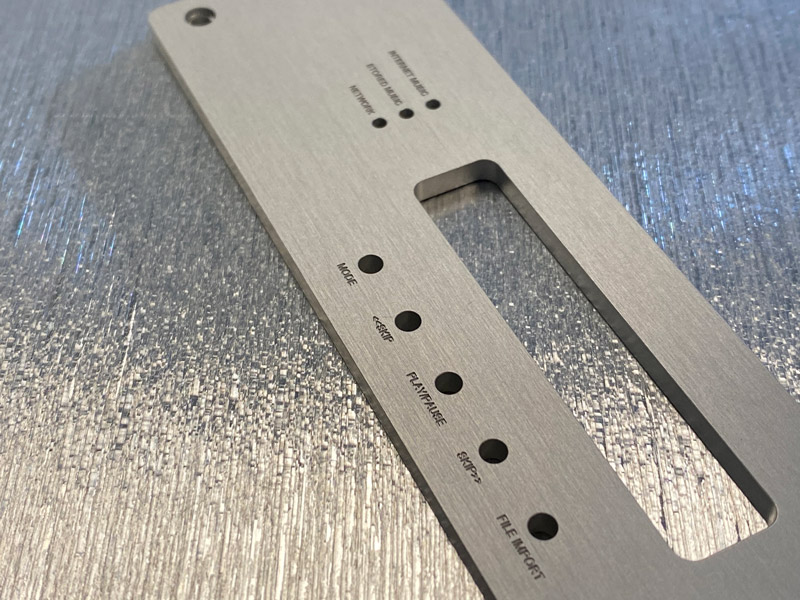

3D CNC Engraving

Reliable - precise - perfect

Noble in the details

Engraving example 1

Engraving example 2

Engraving example 3

For further information please click on the images.

FAQ - 3D CNC engraving in aluminium, copper, brass, bronze, non-ferrous metals and plastic

What is 3D CNC engraving and which materials can be processed?

3D CNC engravings are precise millings and engravings that are created using CNC machines. These machines can create complex designs in various materials such as aluminium, copper, brass, bronze, non-ferrous metals and plastics.

What advantages does CNC engraving offer over traditional engraving methods?

CNC engraving offers high precision and repeatability. They enable complex and detailed designs that would be difficult or impossible to achieve using traditional methods. CNC machines are also faster and more efficient, which reduces production costs.

What areas of application are there for 3D CNC engraving?

3D CNC engraving is used in many areas, including

Industry: labelling of control cabinets and machines.

Art and jewellery: production of decorative elements and pieces of jewellery.

Advertising technology: Creation of signs and logos.

Medical technology: engraving of precise instrument parts

Which machines and technologies are used for CNC engraving?

Various machines and technologies are used for CNC engraving, including

CNC milling machines: For complex 3D engravings and reliefs.

Laser engraving machines: For precise and non-contact engraving, particularly suitable for sensitive materials.

Scribe engraving: For particularly fine lines and contours, often with diamond-coated engraving styli

What are the special requirements for engraving different materials?

Each material has specific requirements:

Aluminium: Easy to mill, but requires sharp tools and suitable coolants to avoid material build-up.

Copper and brass: Softer than many other metals, so they tend to deform and require careful handling.

Bronze: Harder than copper and brass, good for detailed engraving.

Plastics: Can melt easily, so a controlled milling speed and temperature is important.

How does the choice of material influence the engraving technique?

The choice of material has a significant influence on the engraving technique. Harder materials such as bronze require more robust tools and possibly special milling techniques. Softer materials such as plastic require slower milling speeds and careful management of heat generation to ensure a clean engraving.

What services do companies offer in this area?

Companies offer a variety of services, including:

Cutting and sawing: Preparation of raw material.

CNC machining: Milling and engraving to specific requirements.

Surface treatment: Polishing, grinding and coating to improve the final quality of the product.

Laser marking: High-precision labelling for various applications.

Which software is used for the design and programming of CNC engravings?

CAD/CAM software solutions such as Fusion 360 or similar programmes are often used for the design and programming of CNC engravings. These enable the creation of detailed designs and the direct programming of CNC machines.

MWM Gmbh & Co. KG also offers other mechanical services in addition to engraving, such as

▪ Cutting/sawing

▪ CNC processing

▪ Punching

▪ Welding threaded studs

▪ Press in threaded bolts

▪ Laser labeling

▪ Bending

▪ Welding

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de