MWM

CNC processing

CNC machining with over 30 years of experience

fast - inexpensive - competent

We have already been able to convince many well-known companies from a wide range of industries of the advantages that cooperation with MWM GmbH & Co. KG offers.

Our satisfied customers include not only mechanical engineers, the automotive industry, manufacturers of high-end music systems and design products but also companies from the medical, furniture, lighting, sanitary and aviation industries.

Handles and handle strips

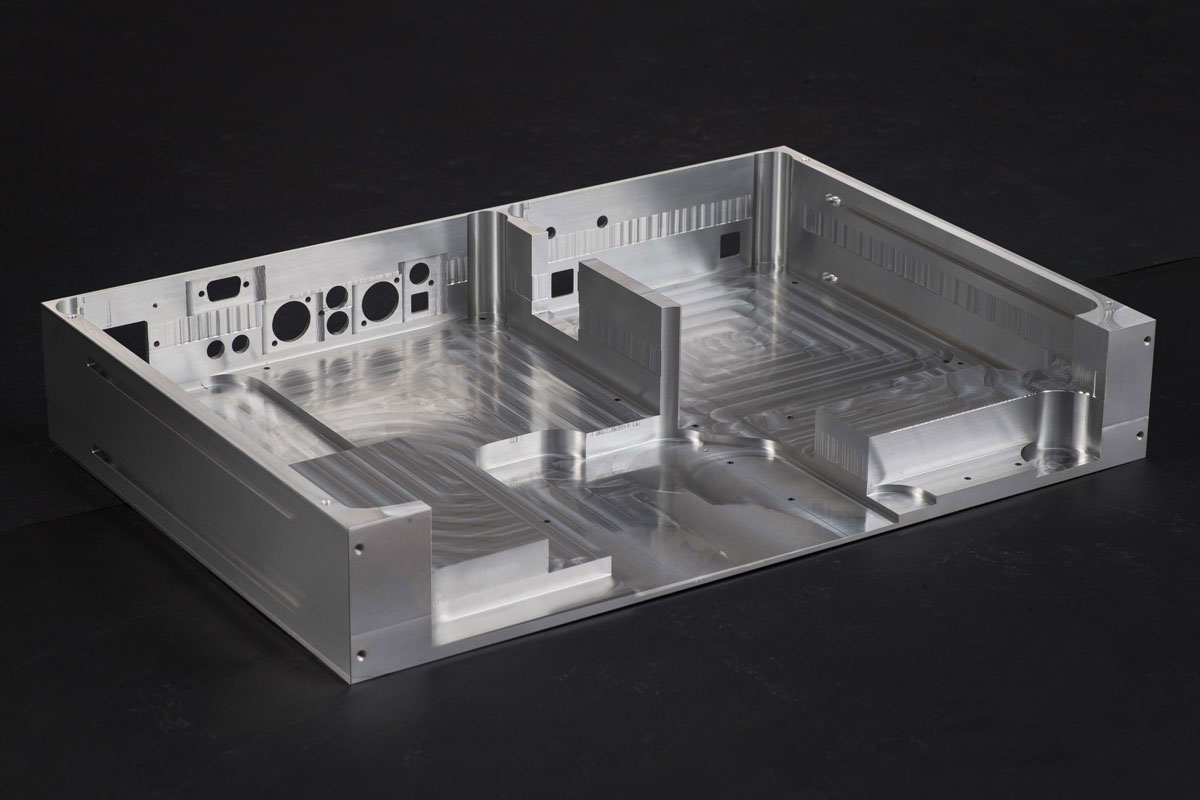

Housing

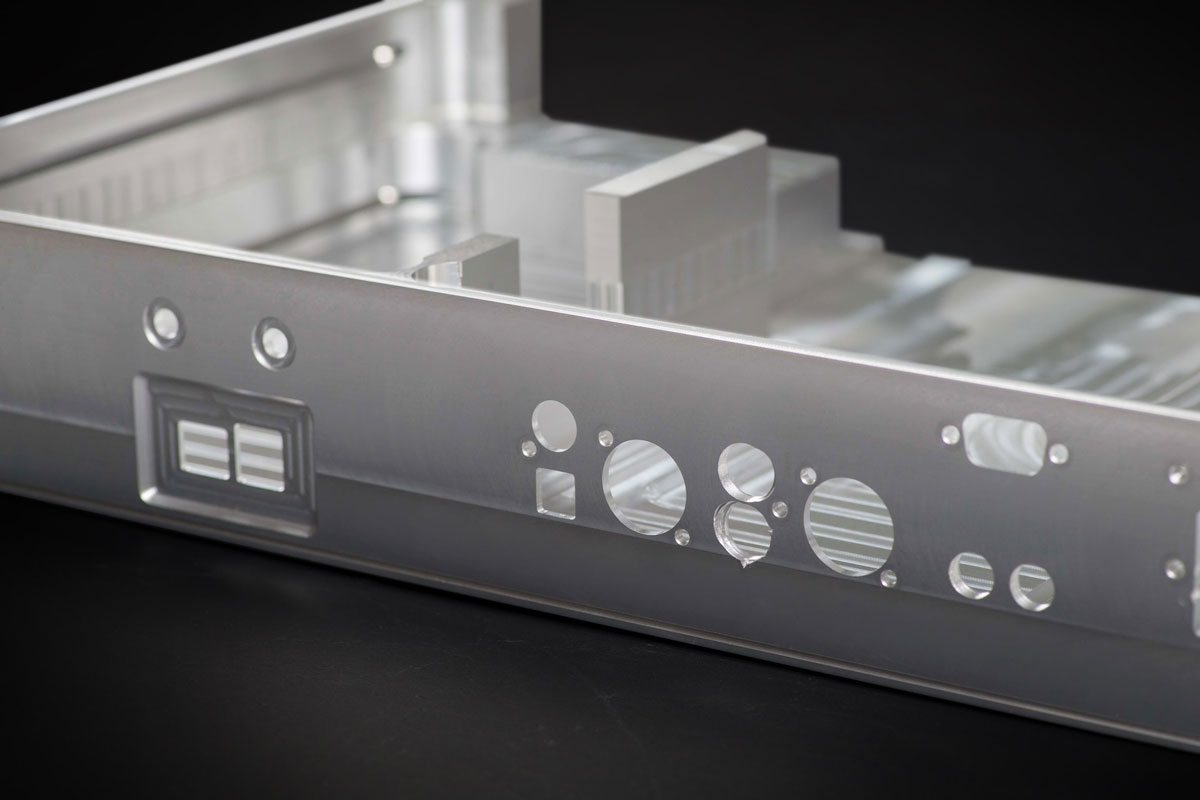

Device back panel

Machine components

For further information please click on the images.

Milling machine

Datron M8 Cube 3-axis

Editing area

830 x 1020 x 245 mm

Material

Aluminum, brass, plastic

Number of revolutions

40.000 1/min

Milling machine

Datron M10 3-axis

Editing area

830 x 1020 x 240 mm

Material

Aluminum, brass, plastic

Number of revolutions

40.000 1/min

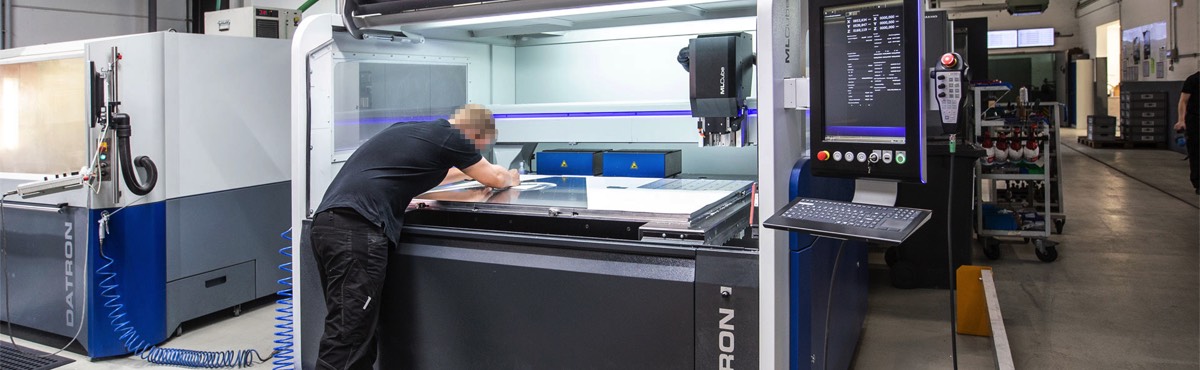

Milling machine

Datron ML Cube 3-axis (2 x available)

Editing area

1020 x 1520 x 245 mm

Material

Aluminum, brass, plastic

Number of revolutions

40.000 1/min

Milling machine

DMC 1035V 3-axis

Editing area

560 x 1035 x 510 mm

Material

Aluminum, stainless steel, brass, plastic

Number of revolutions

12.000 1/min

Milling machine

DMF 260 4/5 axes

Editing area

700 x 2600 x 700 mm

Material

Aluminum, stainless steel, brass, plastic

Number of revolutions

18.000 1/min

Milling machine

EIMA ALPHA / T CONTURA 5-axis

Editing area

1000 x 3000 x 550 mm

Material

Aluminum, brass, plastic

Number of revolutions

24.000 1/min

Milling machine

Haas UMC 1000 5-axis

Editing area

635 x 1016 x 635 mm

Material

Aluminum, stainless steel, brass, plastic

Number of revolutions

15.000 1/min

Do you have any questions about our processing options?

We are happy to help. Call us or write to us.

FAQ - CNC processing

What is CNC milling?

CNC milling (computer numerical control milling) is a subtractive manufacturing process in which computer-controlled milling cutters remove material from a workpiece to shape it into the desired form. Milling tools are moved in different axes to create precise cuts and shapes.

What types of CNC milling machines are there?

There are three main types of CNC milling machines, which differ in terms of the number of axes:

- 3-axis milling: Operates in the X, Y and Z axes and is suitable for simple to medium-difficulty work.

- 4-axis milling: Adds a rotation axis (A-axis) to the 3-axis machine and enables more complex machining operations.

- 5-axis milling: Adds an additional B-axis, which offers maximum flexibility and precision when machining highly complex parts.

Which materials can be processed with CNC milling machines?

CNC milling can machine a variety of materials, including metals such as aluminium and steel, plastics, wood and even ceramics. The choice of material depends on the application and the specific requirements of the project.

What are the advantages of CNC milling?

High precision: CNC milling enables extremely precise machining, which is particularly important for complex and detailed parts.

Repeatability: The computerised control system ensures that each part is produced exactly like the next.

Efficiency: Automation allows large quantities to be produced in a short time.

Safety: Physical interaction between operator and machine is minimised, which increases safety.

What applications are there for CNC milling?

CNC milling is used in many industries, including:

Automotive: manufacturing engine components, gearboxes and other precision parts.

Aerospace: production of aircraft parts that require high precision.

Medical technology: production of surgical instruments and implants.

Furniture manufacturing: Creation of modern and unique pieces of furniture.

Prototyping: Rapid production of prototypes from plastic and other materials.

Which milling tools are used?

There are different types of routing tools, including

End mills: For slotting and profiling.

Face milling cutter: For smooth surfaces.

Ball end mills: For detailed contours and 3D carving.

Drill bits: For precise drilling work.

How do you choose the right CNC milling machine?

The choice of the right machine depends on the specific requirements of the project:

3-axis machines are ideal for simpler parts and less complex geometries.

4-axis machines offer more flexibility and can machine more complex parts.

5-axis machines are the best choice for highly complex and precise machining, but they are also more expensive and more difficult to operate.

How does CNC machining of components work?

The CNC machining process begins with the programming of the CNC milling machine. The programme can be entered locally directly on the CNC milling machine. However, it is also possible to create the programme on a computer using a CAD/CAM system.

We use the latest generation of CAD Autodesk Inventor and Inventor CAM software for programming the CNC programmes. The data set (STP) provided by you enables us to convert 100% of the data into a programme and to fulfil all dimensional specifications.

Once a blank has been cut to size on a CNC saw, the component can be clamped in the CNC milling machine.

Now the CNC machine is set up for machining the component. For this purpose, it must now be determined with which clamping technology the component can be fixed in the CNC milling machine.

There are several clamping options for CNC machining. Either the component is fixed in a vice, a clamping system, a special clamping device or on a vacuum chipboard.

Once the blank has been clamped / fixed, the CNC milling machine can be started.

Each of our CNC milling machines is equipped with many machining tools in a so-called tool changer. This enables a smooth and rapid CNC machining process.

MWM Gmbh & Co. KG also offers other mechanical services in addition to CNC processing, such as

▪ Cutting/sawing

▪ Engraving

▪ Punching

▪ Welding threaded studs

▪ Press in threaded bolts

▪ Laser labelling

▪ Bending

▪ Welding

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de