MWM

Aluminium Components

We are your professional partner and supplier when it comes to the production of aluminium components. Aluminium components are used in almost all areas of industry, both technically and visually. They fulfil many technical requirements where weight savings or corrosion protection are required. Aluminium components can also be used in products that have to meet the highest design standards.

We are your manufacturer, offering you the complete manufacturing package. We procure the raw material for every application and requirement. Naturally with the best surfaces that you will not find anywhere else.

More than 25 years of experience in the production of aluminium components, especially when it comes to decorative surfaces, speaks for itself.

Of course, we also process your material and are happy to advise you on all questions relating to technical realisation, right through to the finished product.

We are happy to support you in the development and design of new products so that you have real added value and no unexpected problems occur later.

The aluminium components we have produced to date are used in the following industries, among others:

The aluminium components we have produced to date are used in the following industries, among others:

Aluminium component:

Shift gate cover with subsequent velour chrome plating.

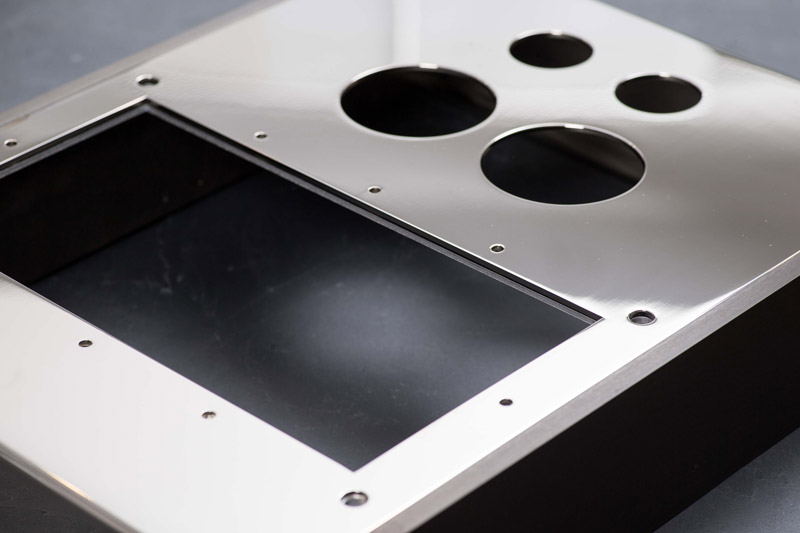

Aluminium component:

Smartphone charging station

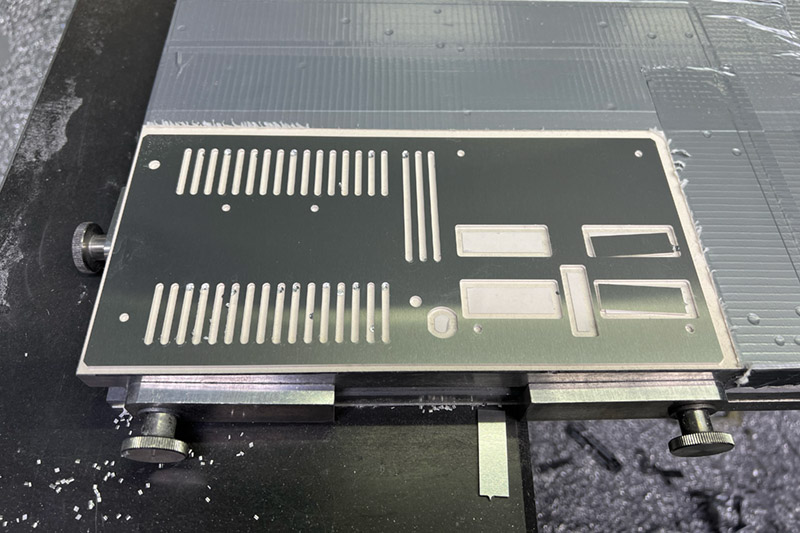

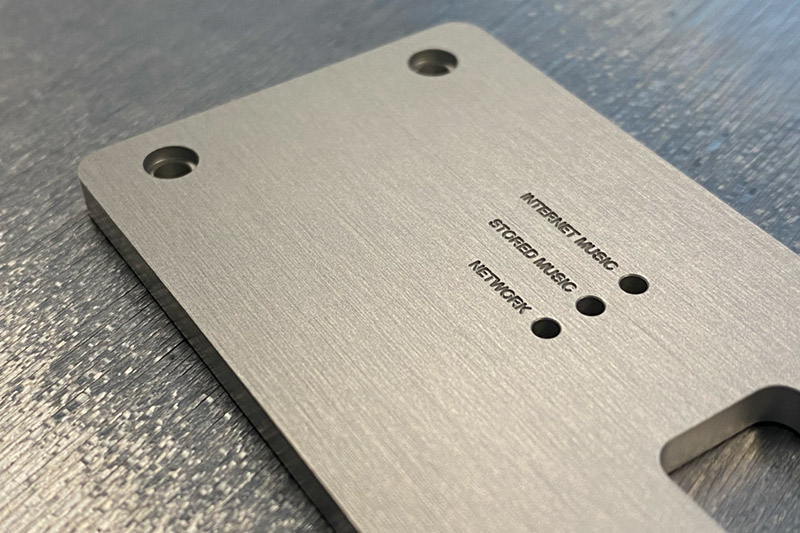

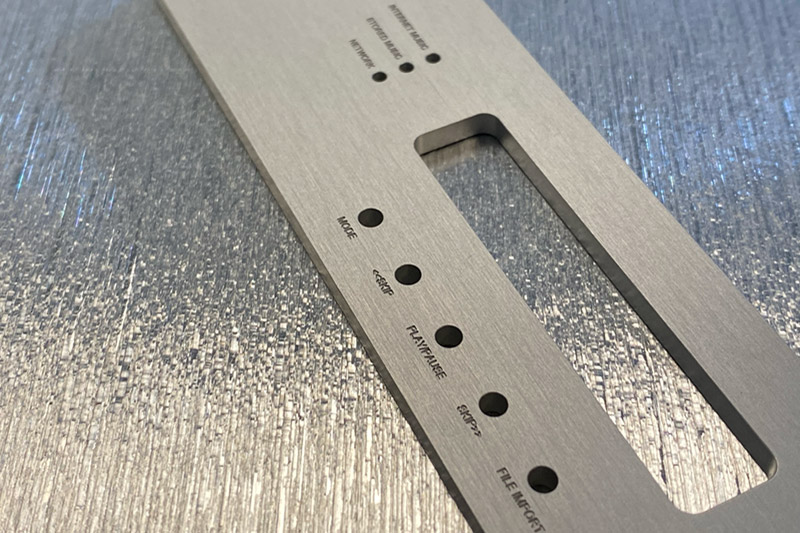

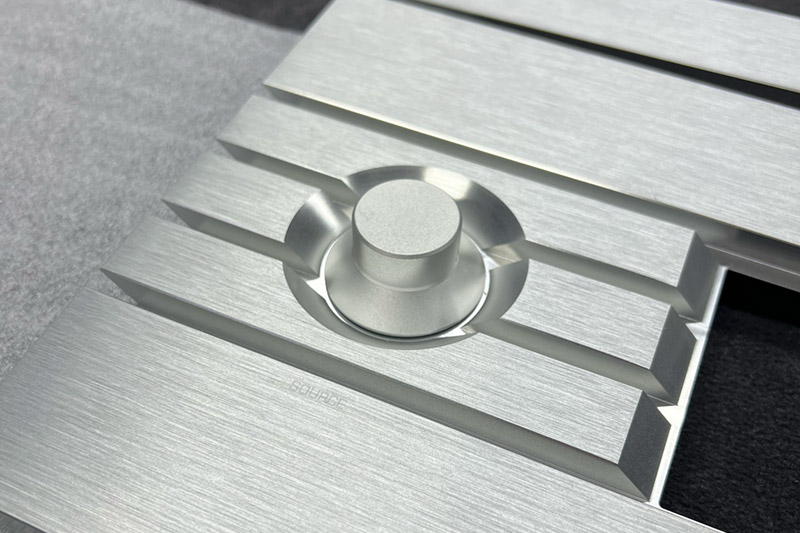

Aluminium component:

Housing front HIFI component

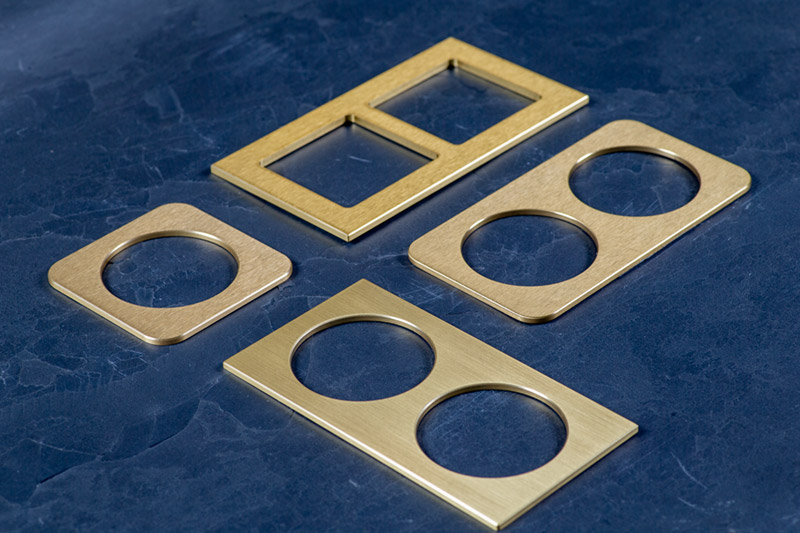

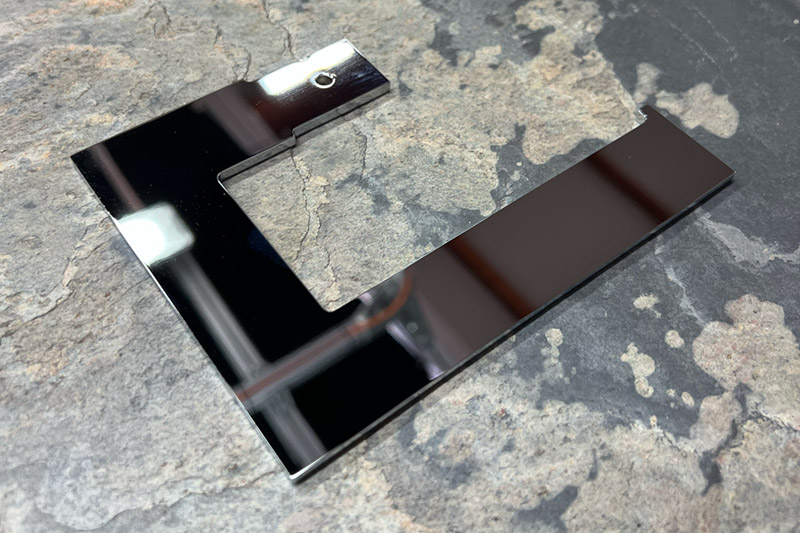

Aluminium component:

Switch frame

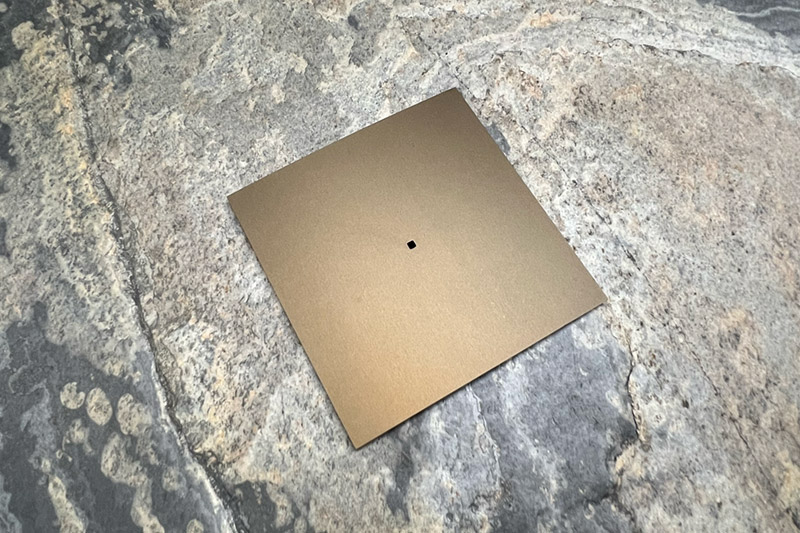

Aluminium component:

Component from the construction industry

Aluminium component:

Tube for furniture

Aluminium component:

Cromed towel rail

Aluminium component:

Luminaire part made of aluminium

Aluminium component:

Component from shipbuilding

... and many other sectors.

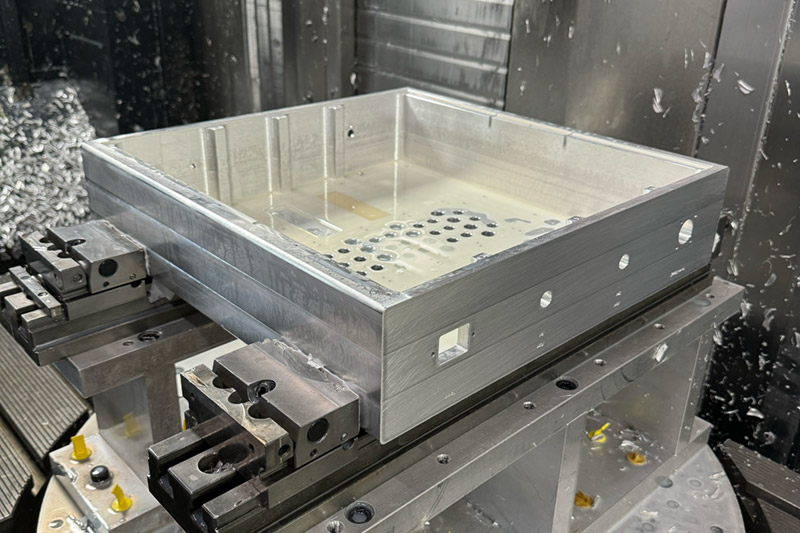

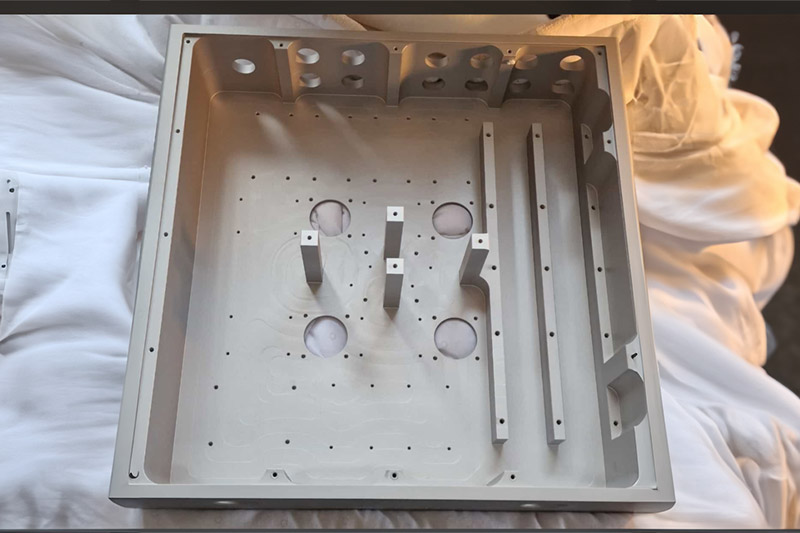

The manufacture and processing of aluminium components

... is a central component of our production processes. Aluminium, a lightweight yet robust material, is used in numerous industries, including automotive engineering, aerospace, shop fitting and mechanical engineering. Its corrosion resistance, high strength and good formability make aluminium a sought-after material. The processing of aluminium requires specific mechanical services that contribute significantly to the shape and functionality of the components.

Examples of aluminium components include housings for electronic components, loudspeakers, furniture handles, hi-fi components, but also smaller components such as switch frames and other miniature components for industry. This component must be precisely moulded in order to protect the sensitive technology inside. Another example is the use of aluminium profiles in the construction industry, which often have to be cut to size and adapted to meet the structural requirements. Various mechanical processing techniques are used for this purpose.

One of the most common processing methods for aluminium is milling. This involves removing excess material from an aluminium blank in order to achieve the desired shape and surface quality. Our CNC (Computerised Numerical Control) machining is a precise milling method that enables the automated production of complex components with tight tolerances. The computerised control of the tools ensures a high level of repeat accuracy, which is particularly advantageous in series production.

During bending, aluminium is formed into a predetermined shape without the material breaking. This method is often used in the production of aluminium profiles or sheets used in architecture or mechanical engineering. Welding is used to join components together. Here, two aluminium parts are fused together using heat. This technique is used particularly frequently in vehicle construction, for example in the manufacture of car body parts.

Sawing is used to cut aluminium plates or profiles to the desired length. It is a basic technique that is used both in pre-production and in the customisation of components in the final stage. Engraving is used to apply markings, serial numbers or logos to aluminium components. Punching, on the other hand, is used to emboss holes or specific shapes in aluminium sheets. This is a fast and efficient process that we often use in mass production.

Finally, our laser marking enables permanent and precise marking of aluminium parts. By using our laser technology, fine lettering, barcodes or other information can be applied directly to the surface without damaging the material. This method is often used in the electronics and automotive industries.

Other product examples

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de