MWM

Press in threaded bolts

Simple - safe - accurate

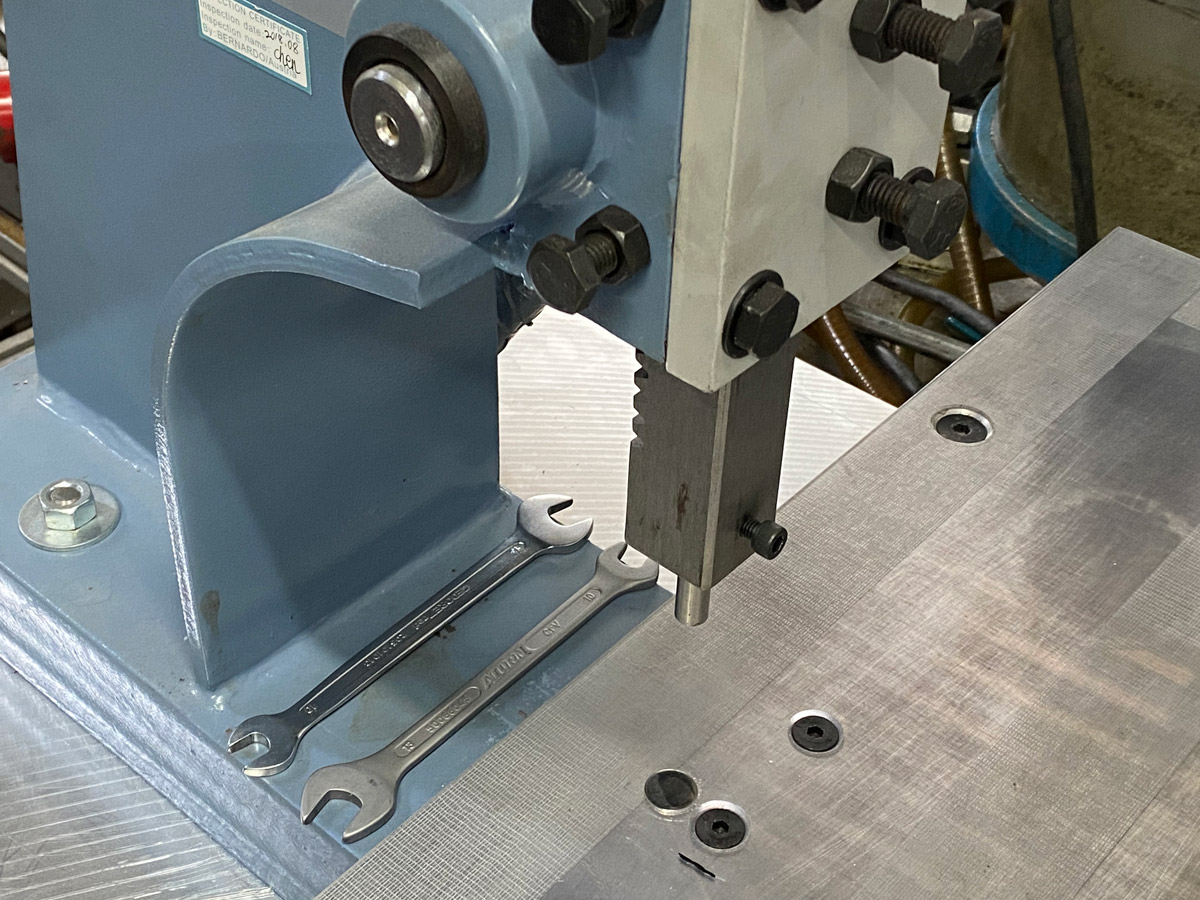

Press-in machine

Product detail 1

Product detail 2

FAQ - Thread insertion

What is a press-fit threaded bolt?

A press-fit threaded stud is a fastening element that is pressed into a component, often sheet metal. It has a knurl or serration under the head that bonds with the surrounding material when pressed in, creating a secure and permanent connection. This enables high resistance to torque loads and ensures that the bolt is firmly seated without damaging the surface.

What are the advantages of press-fitting threaded bolts?

Pressing in threaded bolts has several advantages:

High strength: The connection is highly resistant to torques and press-out forces.

Gentle on materials: As this is a mechanical process, coated or finished surfaces are not damaged.

Precision: The stud always sits exactly vertically in the sheet metal and can be inserted flush with the surface.

Which materials are suitable for pressing in threaded bolts?

Press-in threaded studs can be used in various materials such as steel, stainless steel, aluminium and even certain plastics. The choice of material depends on the specific application and load requirements.

What are the requirements for sheet thickness and hardness?

There are specific requirements for the sheet thickness and hardness when pressing in threaded studs. Typically, they are used in sheet metal from a thickness of 0.5 mm. The sheet hardness should be selected according to the bolt manufacturer's specifications to ensure a secure and durable connection.

How does the press-fit process work?

During the press-fit process, the bolt is pressed into a pre-drilled hole in the sheet metal with high axial force. The material of the sheet flows into the knurling of the bolt, which creates a positive fit. This process prevents the bolt from twisting or coming loose.

What tools are required for press-fitting?

Special tools are required to press in threaded bolts, such as press-in machines and dies. These tools ensure that the stud is pressed in precisely and with the necessary force. There are both manual and automatic systems, depending on the production requirements.

Where is threaded stud insertion used?

Threaded studs are frequently used in sheet metal working, mechanical engineering, the automotive industry and electrical engineering. Typical applications include the fastening of housings, components and structures that have to withstand high loads.

What mistakes should be avoided when press-fitting?

A common mistake is choosing the wrong hole diameter or applying insufficient insertion force, which can lead to a poor connection. It is important to pay close attention to the bolt manufacturer's specifications to ensure a secure and durable connection.

MWM Gmbh & Co. KG also offers other mechanical services in addition to threaded bolt insertion:

▪ Cutting/sawing

▪ CNC processing

▪ Engraving

▪ Welding threaded studs

▪ Punching

▪ Laser labeling

▪ Bending

▪ Welding

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de