MWM

Grinding

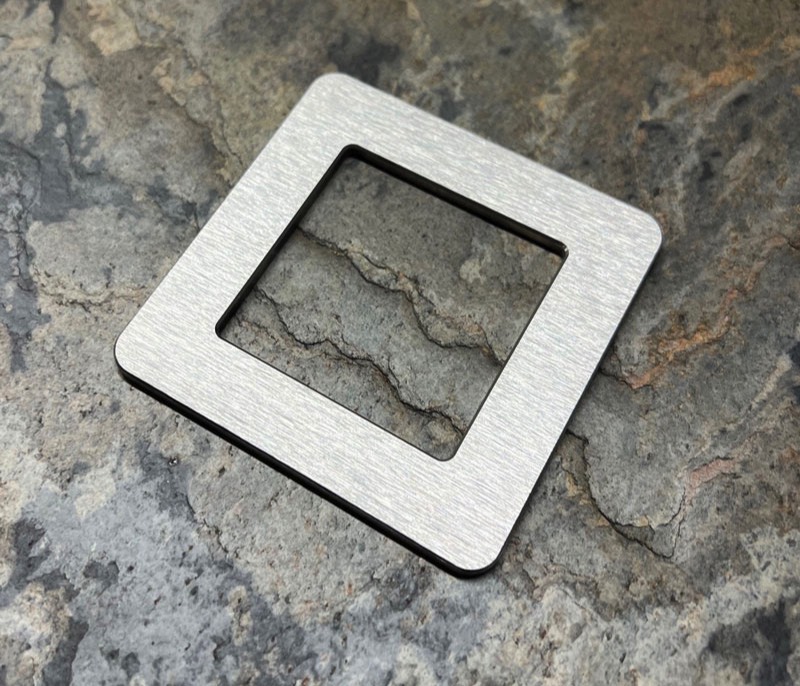

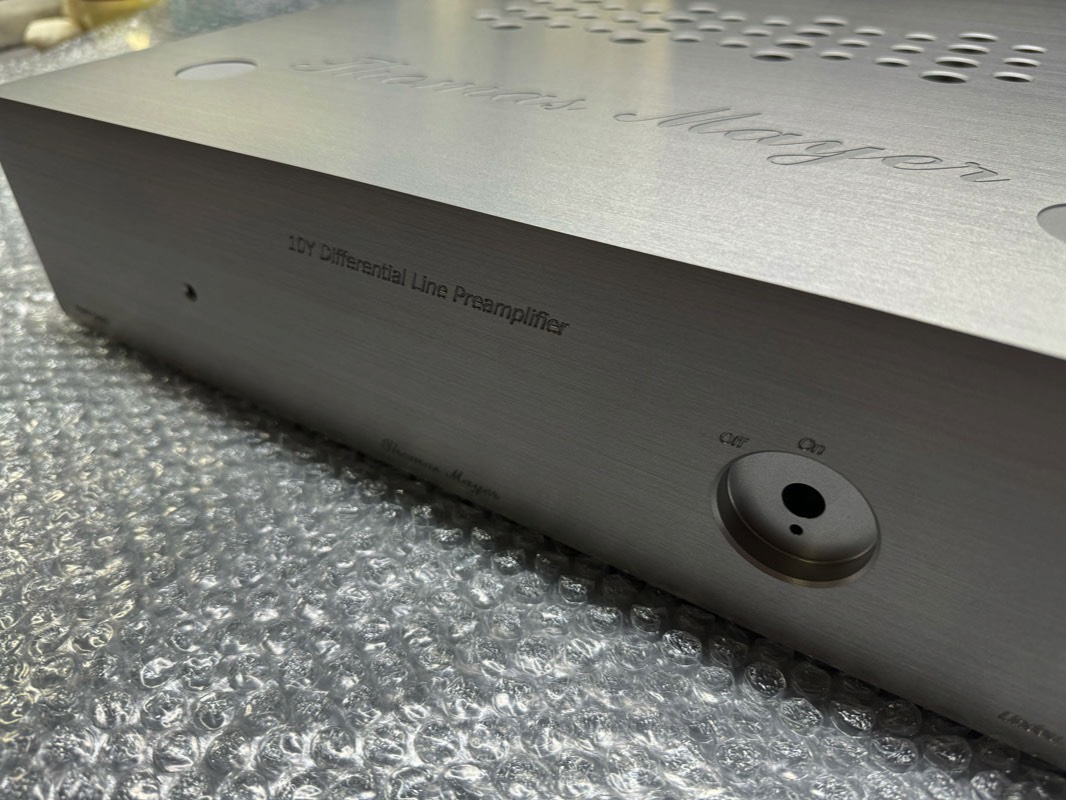

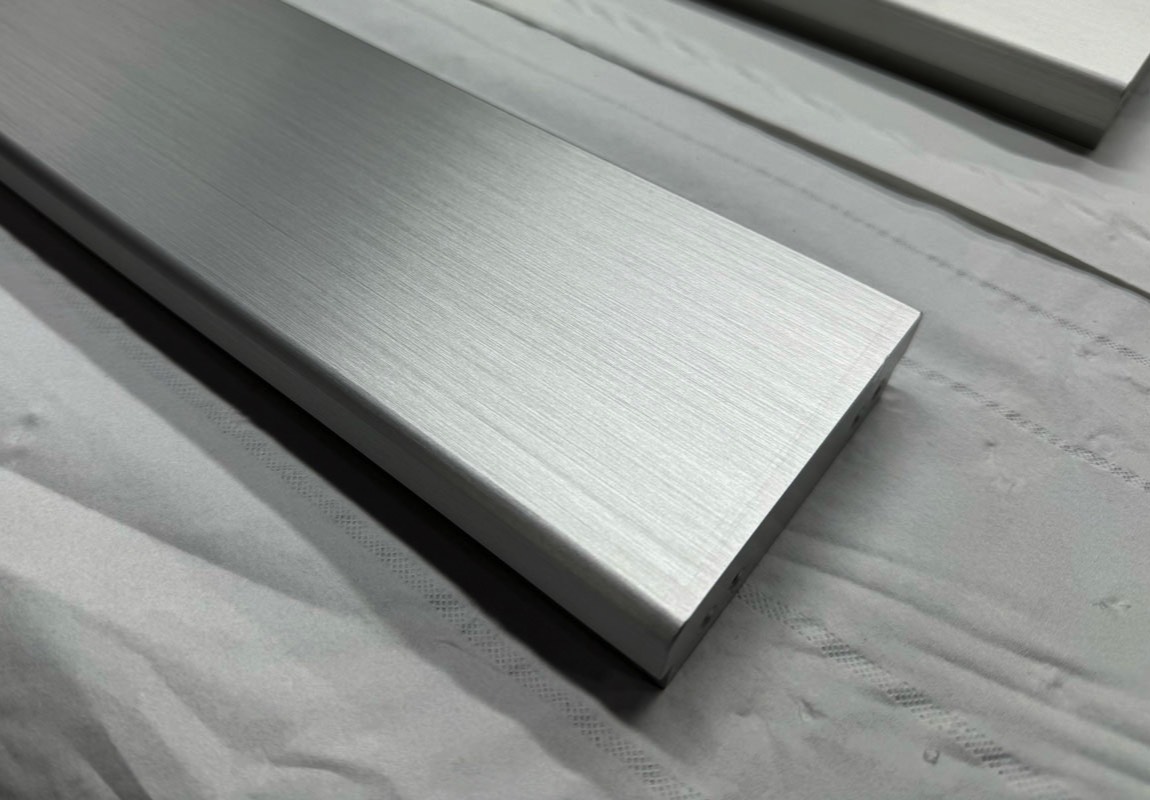

Grinding of aluminum, brass, bronze, non-ferrous metal and stainless steel components

Decorative – clean – perfect – even

Grinding of aluminum, brass, bronze, non-ferrous metal and stainless steel components can be used as a preliminary process for polishing a workpiece. However, grinding aluminum, brass, bronze, non-ferrous metal and stainless steel components can also be a finishing process in surface processing to give the surface of components made of aluminum, brass, stainless steel and other non-ferrous metals an even, contoured appearance.

By grinding aluminum, brass, bronze, non-ferrous metal and stainless steel components, the surface is contoured in the top layer area in order to break the light reflections. Grinding is often used as a preliminary process before polishing, chrome plating and anodizing of aluminum, brass, bronze, non-ferrous metal and stainless steel. Stainless steel components often get their final finish through grinding.

Grinding is a type of surface finishing to achieve finely lined matt surfaces on aluminum, brass, stainless steel and other metals.

The professionals at MWM have many years of experience in surface technology, particularly in the areas of grinding, polishing, matting, glass bead blasting and stainless steel shot blasting of the above-mentioned metals. The MWM team also offers the following processes of electroplating, anodizing, painting and powder coating.

FAQ - Grinding aluminium

Why is grinding aluminium challenging?

Aluminium is a soft metal with high thermal conductivity that tends to smear heavily during grinding. These properties make the grinding process more complex than with other metals and require special techniques and tools.

Which abrasives are recommended for aluminium?

Flap discs, fibre discs and special sanding belts with a suitable coating that prevents the sanding discs from clogging are particularly suitable for sanding aluminium. Sanding papers in various grit sizes are also commonly used, depending on the desired surface finish.

What safety precautions are necessary when grinding aluminium?

Aluminium dust is highly flammable and can be explosive. Extraction systems and personal protective equipment, such as respirators, are therefore required to minimise risks. Attention should also be paid to the correct storage of sanding dust.

How is the oxidation layer on aluminium affected during grinding?

Sanding removes the natural oxidation layer of aluminium, which quickly forms again. This can have an impact on subsequent processes such as gluing or painting, which is why work should continue quickly after sanding.

Can aluminium be polished after grinding?

Yes, aluminium can be polished to a high gloss after sanding. Coarse-grained abrasives are used first and then finer abrasive papers and special polishing pastes. Polishing is carried out in several steps to achieve the desired surface finish.

What are the challenges of grinding aluminium compared to other metals?

Compared to harder metals, aluminium requires less pressure and special abrasives to prevent the grinding wheels from sticking and overheating. The rapid formation of an oxidised layer and the high thermal conductivity are further challenges.

What are the advantages of hiring a contract service provider for grinding aluminium?

A contract service provider has the necessary expertise, equipment and experience to grind aluminium efficiently and safely. As a result, high-quality results can be achieved and all safety requirements can be met at the same time.

What post-processing is required after grinding aluminium?

After grinding, deburring is often necessary to remove sharp edges. This can be done manually with files or by machine. In many cases, polishing also follows to achieve a smooth, shiny surface.

How can grinding wheels be prevented from clogging when grinding aluminium?

Special abrasives with suitable bonds are used to prevent the grinding discs from clogging. These prevent aluminium particles from clogging the disc, which increases the efficiency and service life of the grinding discs.

What surface qualities can be achieved when grinding aluminium?

By using different abrasives and techniques, different surface qualities can be achieved, from a matt to a high-gloss surface. The degree of polishing and the selected grit of the abrasive determine the final result.

MWM GmbH & Co. KG also offers other surface services in addition to grinding:

▪ Polishing

▪ Glass bead blasting / stainless steel shot blasting

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de