MWM

Blasting

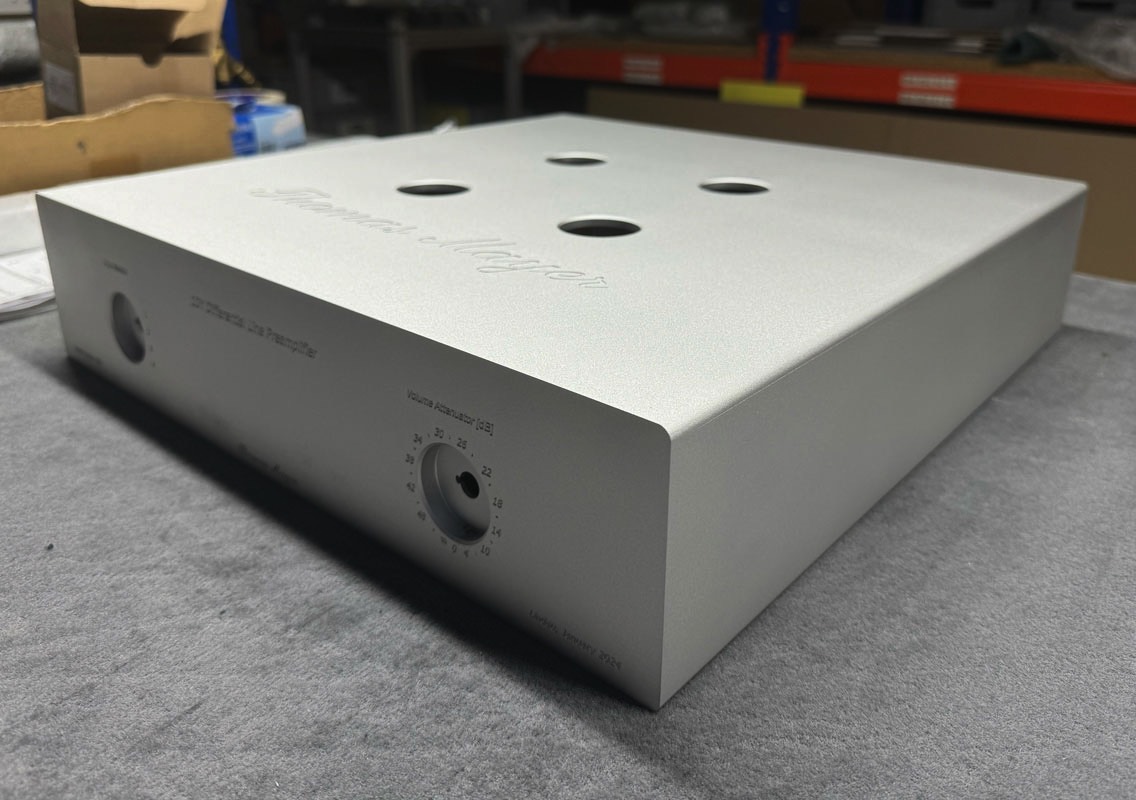

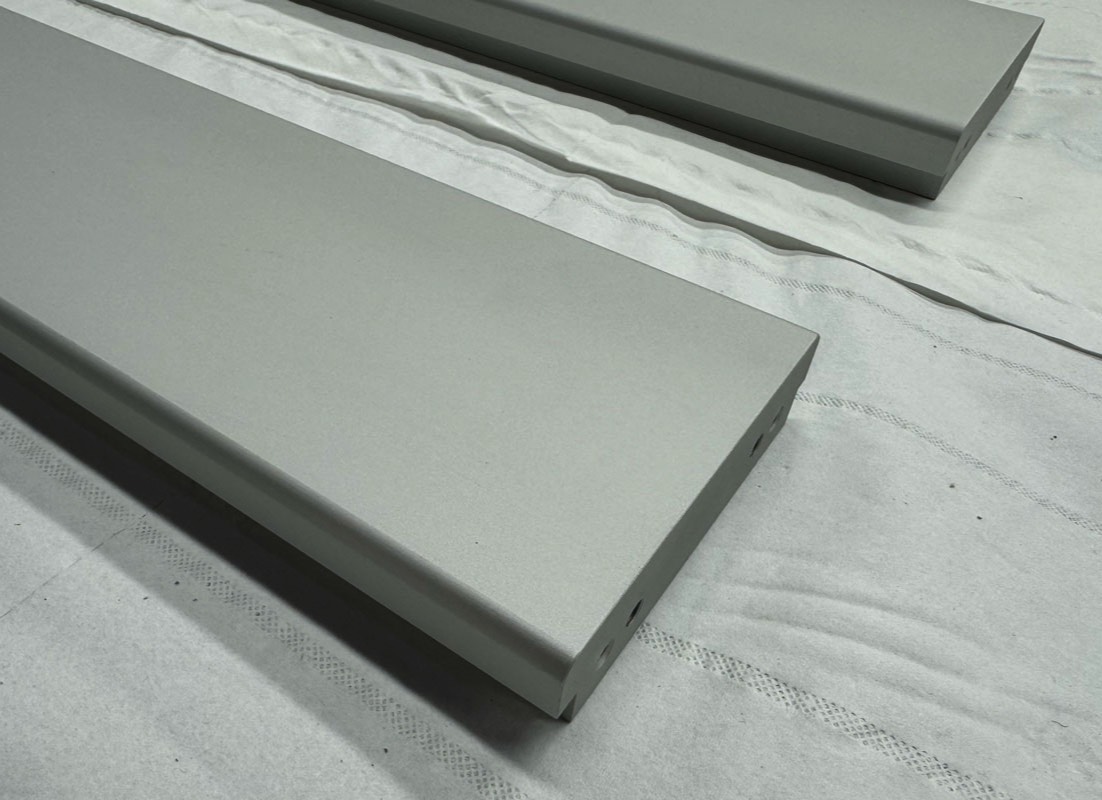

Glass bead blasting – stainless steel shot blasting

Decorative – clean – perfect – even

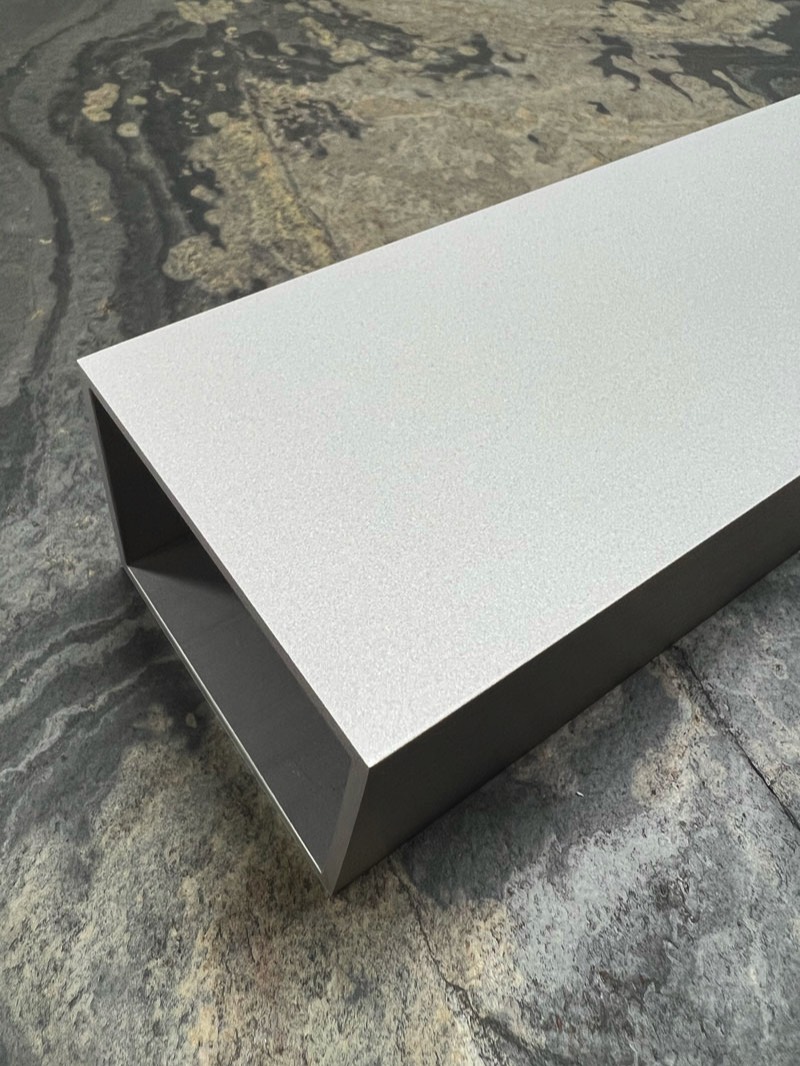

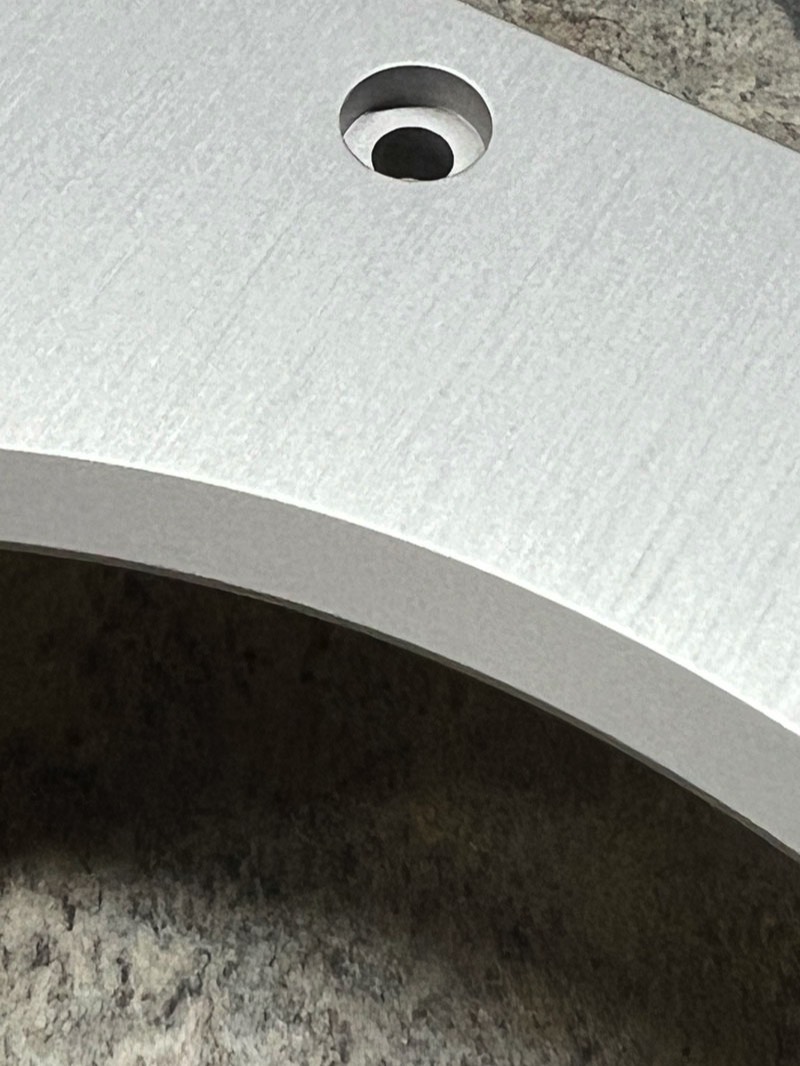

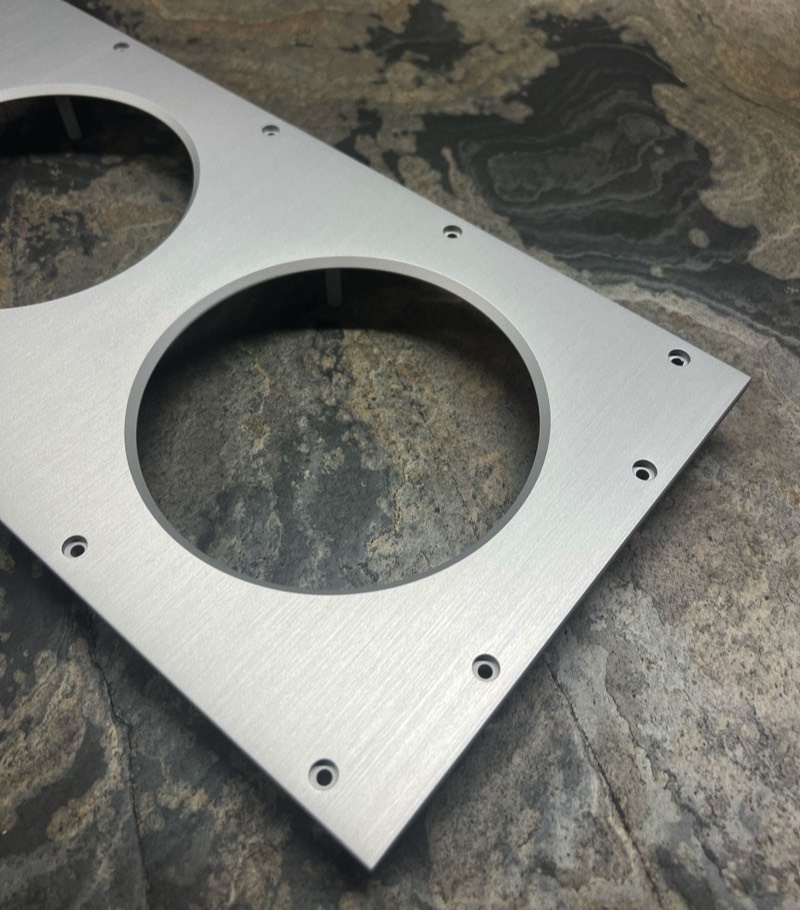

Glass bead blasting is a finishing process in surface treatment to give the surface of components made of aluminum, brass, stainless steel and other non-ferrous metals an even, satin appearance.

Glass bead blasting compacts the surface in the top layer area in order to break the light reflections very easily. Glass bead blasting is often used as a preliminary process before anodizing aluminum. Stainless steel as well as brass and other non-ferrous components usually get this final finish through glass bead blasting.

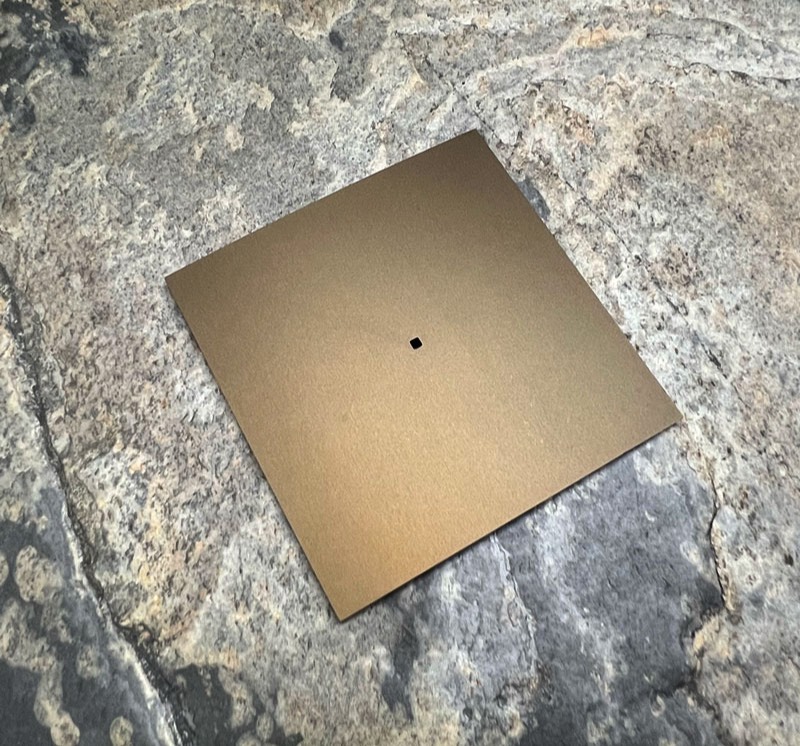

Like glass bead blasting, stainless steel shot blasting is also a type of surface finishing to achieve finely structured matt surfaces on aluminum, brass, stainless steel and other metals.

Stainless steel shot blasting differs from glass bead blasting, among other things, in the use of a different blasting agent. The professionals at MWM have many years of experience in surface technology, particularly in the areas of grinding, polishing, matting, glass bead blasting and stainless steel shot blasting of the above-mentioned metals. The MWM team also offers the following processes of electroplating, anodizing, painting and powder coating.

FAQ - Glass bead blasting / stainless steel shot peening

What is glass bead blasting?

Glass bead blasting is a process in which small glass beads are blasted onto a surface at high speed in order to clean or refine it. It is particularly gentle and results in a matt or silky lustre surface without removing much of the material.

What is glass bead blasting used for?

The process is often used to clean metals such as stainless steel and aluminium to remove welding discolouration, impurities and machining marks. It is also suitable for decorative surface treatments and for preparing surfaces for further coatings.

What are the advantages of glass bead blasting?

Gentle material removal: It removes dirt and surface defects without damaging the base material.

Versatility: It can be used on a variety of materials, including metals, plastics and glass.

Recyclability: Glass beads can be used multiple times, making the process cost-effective and environmentally friendly.

Are there any disadvantages to glass bead blasting?

Limited sanding effect: The process is less suitable for heavy material removal.

Sensitivity to moisture: Oxidation may occur in humid environments.

Necessary control: If used incorrectly, the glass beads can clump together and damage the surface.

How does glass bead blasting differ from other blasting processes?

Glass bead blasting is gentler than sandblasting and is more suitable for sensitive surfaces. Compared to dry ice blasting, it offers mechanical cleaning, whereas dry ice blasting relies on thermal effects. In contrast to steel blasting, it is less abrasive and does not produce metal chips.

For which industries is glass bead blasting particularly suitable?

Glass bead blasting is used in many industries, including the automotive, aerospace, medical technology and food industries. It is ideal for applications that require a clean and even surface, such as in preparation for galvanising or to prevent corrosion.

What grit sizes are used for glass bead blasting?

The choice of grit depends on the application. Fine grits are used for a smooth surface and fine details, while larger grits are used for more aggressive applications where a more pronounced surface change is desired.

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de